- Home

- PRODUCTS

- DISCHARGE WATER DEPURATION PLANTS AND FILTER PRESS

DISCHARGE WATER DEPURATION PLANTS AND FILTER PRESS

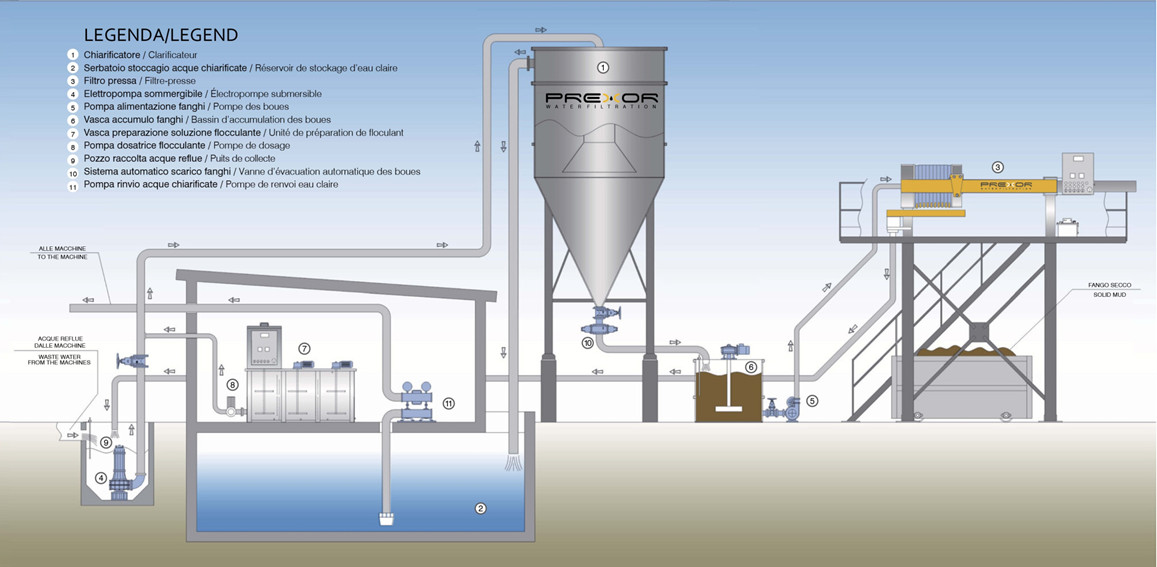

THE PLANT MAY BE CONSIDERED AS HAVING TWO SECTIONS: THE FIRST IS DEPUTED TO THE PURIFICATION OF THE DISCHARGE WATER (DISCHARGE WATER PURIFICATION PLANT), THE OTHER TO THE DEHYDRATATION OF THE RESULTS MUD (FILTER PRESS).

The waste water coming from the working processes is conveyed into the collecting well (9) where the submersible electric pump (4) is located for the lifting of the same, completely automated, which sends them to the clarifier (1). The clarification is based on the principle of sedimentation of suspended particles in the water, accelerated sedimentation through the aid of appropriate polyelectrolytes (flocculant) whose type is established from time to time depending on the type of particles to be sedimented. In the delivery pipe the flocculant solution obtained in the preparation unit (7) is injected by the metering pump (8). The sludge is deposited on the bottom of the clarifier, from which it is periodically discharged by the automatic sludge discharge valve (10), while the clear water that flows from the top is collected in the special storage tank (2) from which it is sent to the factory through the return pump (11) to be reused in the working processes. The sludge of derivation is collected in the sludge accumulation tank (6) and sent through the appropriate mud pump (5) to the filter press (3). at the end of the process it appears that the recovery of water is almost total, about 98%, thus eliminating the drawback of the difficulty in finding water from the subsoil.