- Home

- PRODUCTS

- IMPIANTI BIOLOGICI

BIOLOGICAL PLANTS

WATER TREATMENT

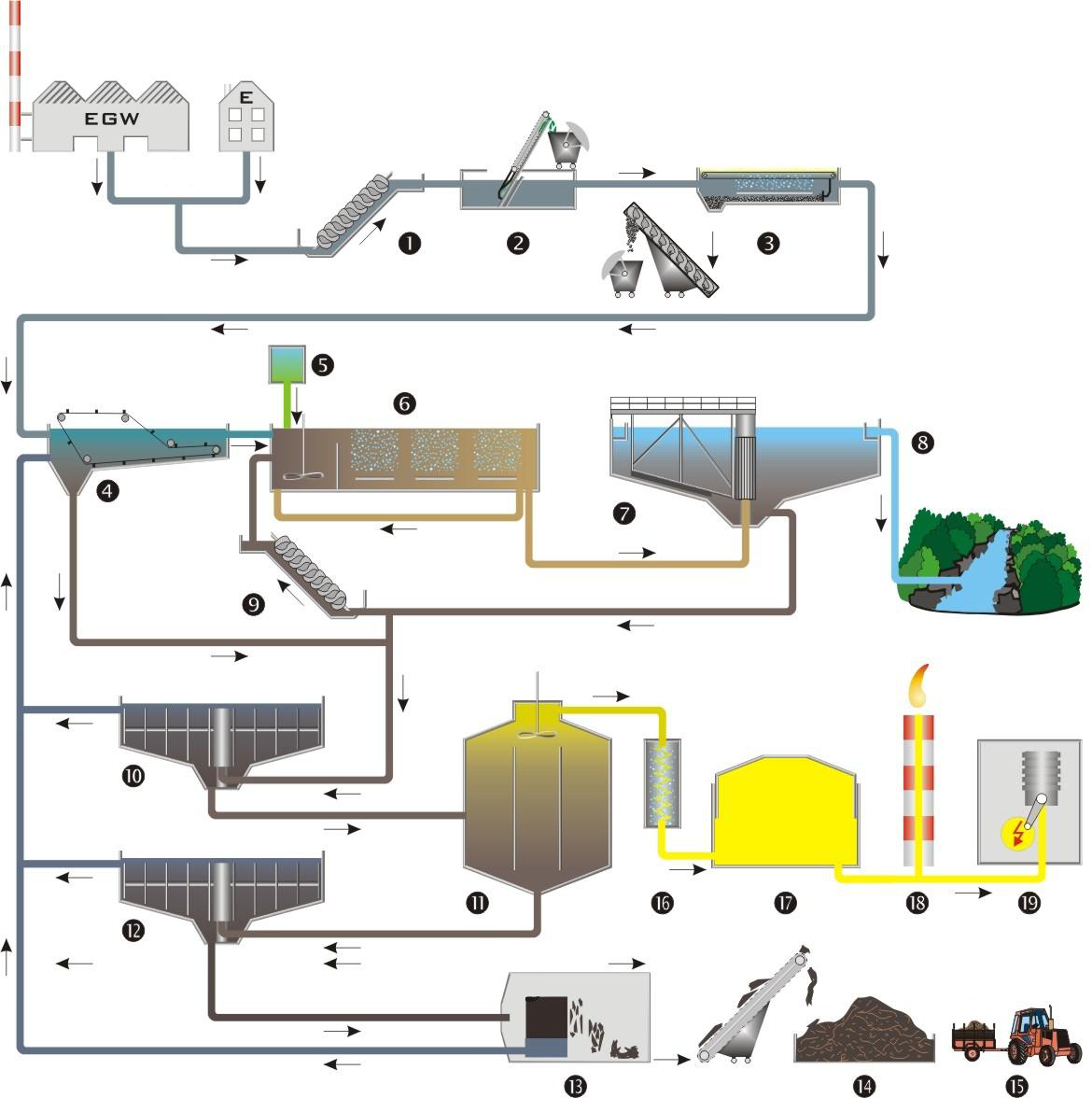

Waste water is collected from the individual sewage networks and conveyed through collectors to the sewage treatment plant. In many cases it is essential to lift (1) the sewage conveyed by the manifold to send them to the subsequent treatment stages.

As the first treatment inside a purification plant we find the grating (2), which is used for the removal of coarse material (pieces of plastic, wood, Hyghieneartikel, stones, paper, etc.) all this, which could otherwise clog pipes and pumps. The grill is washed, pressed and taken to landfill.

In the desoleatura sandblasting (3) the separation of the sands by natural sedimentation takes place, while the separation and the rising of the oils and fats on the surface is favored by insufflation of air which, assuring a limited turbulence also prevents the sedimentation of organic substances.

In the primary sedimentation tank (4) the gravity separation of the sedimentable solids takes place. The sludge that accumulates on the bottom of the tank is driven by the bottom blade of the scraper bridge in the collection hoppers and from these are then taken to be sent to subsequent treatments. At this point the mechanical treatments terminate, which have removed about 1/3 of the organic load.

The elimination of dissolved substances and suspended solids takes place in the activated sludge tank (6). This process is based on the metabolic action of microorganisms p.e. bacteria that use organic substances and oxygen dissolved in the sewage for their activity and reproduction. In this way, flakes are formed consisting of colonies of bacteria easily disposable in the subsequent sedimentation phase. For optimal absorption of the substances sufficient oxygen is needed, which is supplied by insufflation of air from the bottom.

The separation of the sludge flakes from the aerated mixture is obtained by sedimentation in the final sedimentation tank (7). A scraper bridge collects the sedimented mud. A part of the activated sludge is circulated in the aeration tank (9) and the surplus part is sent to the subsequent treatment. The water leaving the final sedimentation can be defined at this point clean and can therefore be returned to the surface water course (8).

In addition to mechanical and biological processes, other treatments are also needed to limit nutrients such as nitrogen and phosphorus in the final discharge, substances that can lead to hypertrophy problems in rivers and lakes. The removal of nitrogen takes place through biological processes through special bacteria in the oxidation tanks, while for the elimination of phosphorus a chemical process is used, which consists in the addition of a flocculant product (eg iron salts) during the purification process.

SLUDGE TREATMENT

The sludge of primary and secondary settling is pumped into the pre-thickener (10), where the concentration of solids is increased and consequently the sludge volume is reduced. The sludge is sent to the digester (11), a closed cylindrical artifact, where it remains about 20 days in anoxic environment at a temperature of 35 ° C. specialized bacteria reduce the organic substance and transform it in part into inorganic substances, producing as a result of their metabolism a gas with a high content of methane (biogas). The gas produced is accumulated in the gasometer (17) and used as an energy source for the production of electricity and heating. The sludge, digested and almost free of odors, is pumped into the post-thickness (12) to further reduce moisture.

With mechanical dehydration (13) by belt press or centrifuge, the mud volume is reduced by six times. The dehydrated sludge has a semi-solid consistency that allows it to be easily used in agriculture, composting or landfilling.